If you work in the electrical train track engineering industry, you know the importance of safety and the potential dangers of the job. One concern is fall protection for workers working on overhead rail systems.

Overhead rail systems are essential for the operation of electric trains, but they also pose a significant risk to workers who are required to access them.

This article will discuss the importance of overhead rail systems in providing fall protection for workers on electrical train tracks. We will also be covering the different types of overhead fall protection systems

We will also provide tips and best practices for properly designing and installing these systems. Whether you are a seasoned professional or new to the field, this article will provide valuable information to keep you and your team safe on the job.

So, let’s dive in and learn more about fall protection overhead rail systems.

1. Importance of Fall Protection System

A fall protection system is designed to prevent workers from falling from heights while working on the overhead rail systems, which, unlike a sectionalizing switch, can be even 50 feet above the ground. These systems can include anything from harnesses and lanyards to guardrails and safety nets.

The systems are designed to provide a secure anchor point for workers to attach their safety equipment to while they work and prevent accidents and injuries, one of the vital importance of a fall protection system. According to the Occupational Safety and Health Administration (OSHA), falls are the leading cause of death or severe injury in the construction and maintenance industry.

Next, a fall protection system protects the workers and the company from potential legal issues and liability in case of an accident. Many countries have strict regulations requiring employers to provide fall protection for workers working at heights. Hence having the protection systems helps employers comply with these regulations, saving them from lawsuits.

A fall protection system also minimizes downtime and lost productivity caused by accidents and injuries. Implementing fall protection systems allows workers to feel safe and secure while on the job, consequently increasing their productivity and morale.

Overall, fall protection is a vital part of overhead rail systems engineering. It’s essential to stay informed about the latest fall protection technologies and best practices to ensure your workers are always protected.

2. Benefits of rigid rail fall protection systems

As a professional working on overhead rail systems for electric trains, you’re likely familiar with the various fall protection systems available. One type of system that has been gaining popularity in recent years is the rigid rail fall protection system.

Rigid rail fall protection systems consist of a rail permanently attached to the structure, such as a building or bridge, and a trolley moving along the fence. A trolley is connected to the worker via a harness, allowing them to move freely along the rail while protected from falls, as shown below.

Here are some of the significant benefits that make these particular systems popular:

- Flexibility: Workers can work on different rail system areas without disconnecting and reconnecting their harnesses. They can also be used for multiple workers simultaneously, making it a more efficient and cost-effective solution.

- Extremely durable and long-lasting: These systems are often made of steel, aluminum, or stainless steel, which means they can withstand harsh weather conditions and heavy use. This makes them ideal for outdoor and industrial environments.

- Better fall protection: Unlike the other types of systems, rigid rail fall protection systems are designed to stop workers from falling if they slip or trip. They also offer a higher level of mobility, which means workers can move around the rail system more efficiently, reducing the risk of accidents.

- Versatile: Rigid rail fall protection systems can be used on new construction projects and retrofitted onto existing structures. They can also be used for permanent and temporary fall protection, making them an excellent option for large construction projects and maintenance work on existing systems.

- Relatively easy to install, maintain, and repair: They come in prefabricated sections that can be easily assembled and installed on-site. The rail can be mounted directly to the structure, and the brackets and clamps used to secure it are typically simple to install.

Finally, all these rigid rail fall protection systems ensure that regular inspection and maintenance are relatively straightforward.

3. Types of overhead fall protection systems

To ensure the safety of workers, it’s essential to understand the different types of fall protection systems available for overhead environments.

The personal fall arrest system

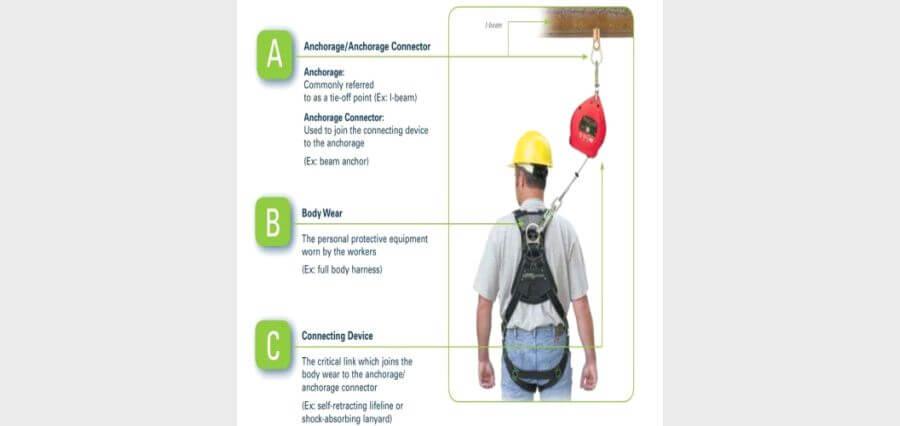

This type of system is designed to stop six feet or more falls before they can cause injury. It typically includes a harness, a lanyard, and an anchor point.

The worker wears the harness, the lanyard attaches the worker to the anchor point, and the anchor point is securely attached to the structure.

The guardrail system

This system is designed to physically block workers from falling by creating a perimeter barrier around the work area. It is specially designed to prevent workers from falling from the edge.

Guardrail systems can be permanent or temporary and can be made from various materials, such as steel or aluminum. Guardrails are often used when there is a potential for a fall from a height of six feet or less.

The safety net system

This system is designed to catch workers who fall from a height of more than 50 feet.

Safety nets are typically made from a strong and durable material such as nylon or polypropylene and are placed under the work area to catch workers who fall.

· Fall restraint system

This type of system is designed to prevent a fall from occurring by limiting the worker’s mobility.

Fall restraint systems can include railings, barriers, or other physical obstacles placed around the work area to prevent workers from reaching the edge of the structure.

Whether you choose a personal fall arrest system, guardrail system, safety net system, or fall restraint system, each one offers unique benefits and should be selected based on the specific needs and requirements of the job site.

In Closing

Fall protection is essential when working on overhead rail systems for electric trains. Various fall protection systems are available, each with unique benefits and limitations.

As an engineer or safety professional, it’s essential to consider the specific needs of the job site and choose the right type of system to ensure the safety of workers. Remember to regularly inspect and maintain the fall protection system and ensure that workers are adequately trained to use it.

Keeping workers safe is essential to keep the operation running smoothly and efficiently.