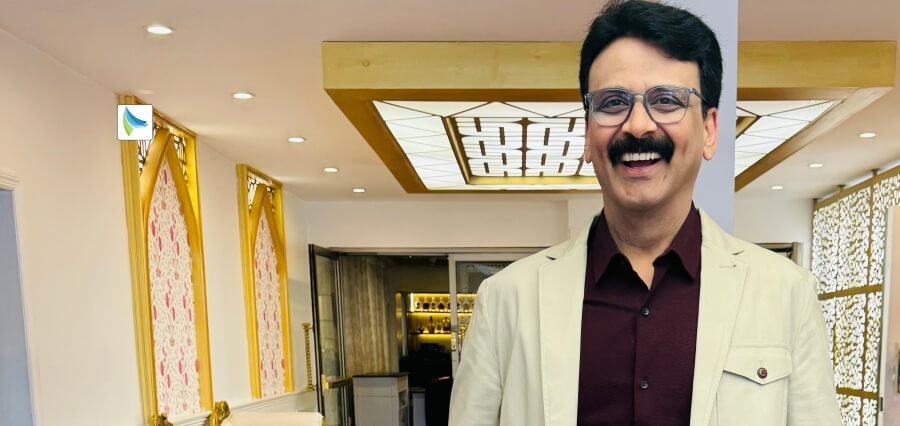

In today’s world of electronics manufacturing, there is ever-increasing pressure to shorten the time-to-market range. Successful application development and test strategies can refine the production process and help drive down and control the cost of the test. Meet Bob Kenney, Vice President, Global Supply Chain, and CPO of Teradyne, who has mastered the art of effective supply chain management.

Bob is an industry-leading executive offering consistent achievements in articulating, developing, and executing supply chain strategies to deliver the required results. His diverse management expertise, combined with forward-thinking business leadership and entrepreneurial agility, has resulted in large-scale change implementations which reduced production costs and improved performance across the global Supply Chain operation. He believes that one cannot ramp experience; however, you can use collaborative customer-centric supply chain designs with shared investments.

Teradyne plays an integral role in the technology industries that change the world. Teradyne delivers manufacturing automation across industries, applications, and the world. It solves complex test and automation challenges and enables businesses to achieve higher production volumes and high-quality outputs.

Insights Success caught up with Bob to get a hold of his expertise and vision for his company.

Below are the highlights of the interview:

Brief our audience about your journey as a business leader until your current position at Teradyne. What challenges did you have to overcome to reach where you are today?

1980’s

Scaling internal manufacturing and new product introduction for the volatile immature ATE industry, east and west coast.

Develop and consolidate a capable US-centric supply chain to scale up and down with the ATE industry.

Implement factory constraint-based software applications to optimize factory capacity while scaling up and down. Implement a Total Quality Management System throughout the organization and supply chain to improve quality and decrease cost.

Implement a capacity planning methodology to align business unit demand with the necessary factory capacity, poor man’s S&OP.

1990’s

Implement a supply chain simulation capability to improve responsiveness to customer requests.

Scaled PCBA capacity on the east coast and opened new PCBA capacity on the west coast.

Outsourced PCBA assembly in the US.

Implemented software application “glass pipeline” using Kinaxis to have visibility at the component level through our contract manufacturers. This enabled gating part visibility at the supplier level, spend analysis at the component level, and simulation capability.

2000 – 2010

Outsourced and off-shored final assembly and test Operations for product divisions, driving 80% of company revenue.

Co-partnered with CIO to implement Oracle ERP and a Data Warehouse across the company to enable global commerce.

Created a Business Process Engineering group to drive process efficiencies across all business units.

Created International Procurement Office in China and Singapore to focus on local supply to support outsourced products.

Transitioned our logistics operations from shipping off the back dock in North Reading to shipping from Suzhou, China, to 14 different free trade zones worldwide.

2010 – 2020

Reduced the time to product cost targets through NPI sourcing with engineering during Path 1 development cycle.

Transitioned 80% of product spend to the low-cost regions realizing multi-millions of cost down.

Implemented “Break the Glass” business continuity plans for products representing 80% of revenue.

Established a Supplier Engineering organization in Costa Rica to support and maintain component specifications and approved supplier list for the Teradyne enterprise.

Developed a responsiveness strategy focused on a customer-centric supply chain that enabled 100% ramp capability within one quarter.

Outsourced Memory and ETS products acquired through acquisition to SEA utilizing a new EMS provider.

Localized the material pipeline for Memory and ETS products in SEA.

Participated in due diligence for Universal Robots, Mobile Industrial Robots, and Auto guide.

2020 & Beyond

Worldwide Covid recovery – implemented a focused geographic tracking by the supplier to manage the safety of employees and capacity risk.

Semi Supply Chain Crisis – established custom component stocking levels mitigated revenue disruption through 2020 – 2021. Extension of lead times, forecasts and established a forward lean using our balance sheet to manage inventory. Utilizing our close executive relationships to manage the buy/sell unique dependency in the Semi ecosystem.

Enabled ramping IA businesses by ramping constrained suppliers by recommending and implementing alternative components. Leverage key test supplier relationships to mitigate component shortages.

Strategically shifting our Business Continuity strategy from “Break the Glass” to a dual source geographic strategy for products generating 90% of revenue.

Tell us something more about Teradyne, its mission and vision.

Our mission is to test the future of electronics and improve global manufacturing.

We aim to ensure the power of electronics can be confidently trusted to inform, enrich and protect our lives.

We also aspire to improve global manufacturing through the application of advanced automation.

Enlighten us on how you have impacted the Industrial Automation niche through your expertise in the market.

Scaled from a local Danish/European supply chain to a worldwide supply chain by leveraging our test supply chain knowledge and capability.

Developed a multi-source competitive supply chain in the highest risk areas relative to cost, quality, and deliver.

Established an internal factory capacity/ investment and outsourcing model to enable scale and cost efficiencies.

Developed a commodity-focused team to drive cost, quality, delivery, and risk protection.

Enabled the development and implementation of a quality-focused organization to drive quality standards and component specifications in manufacturing and throughout the supply chain.

Integrated all IA products into the central component engineering system to enable engineering designs.

Enabled “what if” simulation capability to enable business growth scenarios and gating part analysis to minimize delivery risk.

Develop an outsourcing business case for Auto Guide and MIR.

Established an electronic sourcing methodology by leveraging existing processes for PCBs, FPGAs, and complex electro-mechanical commodities.

Describe in detail the values and the work culture that drives your organization.

Fact based problem solving, transparency, knowledge power vs positional power, honesty and integrity, diversity, equity, and inclusion.

Relationship principles:

Invest early

Use the relationship map

Honest dialogue

Use the influence model

Have fun.

Leadership principles:

Make decisions before the path is clear

Articulate your strategy

Know your competition

Team development through returning authority to your team

Teamwork

At Teradyne, we believe that fostering a diverse, equitable, and iclusive culture will build a stronger and more resilient company for our employees, customers, and communities.

Honesty and Integrity

We take pride in our work and expect employees to take personal ownership in upholding the company’s reputation.

A Company Without Doors

We are driven by creativity and diversity of thought. We foster an open environment where candid discussions are not only encouraged, they are expected.

Customers Count on Us

We partner with our customers every step from idea to the final product, maintaining the highest standards to ensure satisfaction.

Undeniably, technology is playing a significant role in almost every sector. How are you leveraging technological advancements to make your solutions resourceful?

Developed a digital transformation road map to support the growth of the test and Industrial automation business.

Developed critical decision support business processes and technology investments to enable scale through an outsourced supply chain.

Developing an automated decision support application to improve customer responsiveness, efficient use of inventory, and risk support for EOL material and product line architecture.

Where do you envision yourself to be in the long run and what are your future goals for Teradyne?

Break out of the test business 50/50 market share position with the most efficient testers and supporting supply chain to achieve a +60% share.

Enable the IA product lines to achieve $1B in sales in the mid-term by creating a Responsive, Reliable, Resilient supply chain with competitive cost and quality.